2 月 . 10, 2025 09:54

Back to list

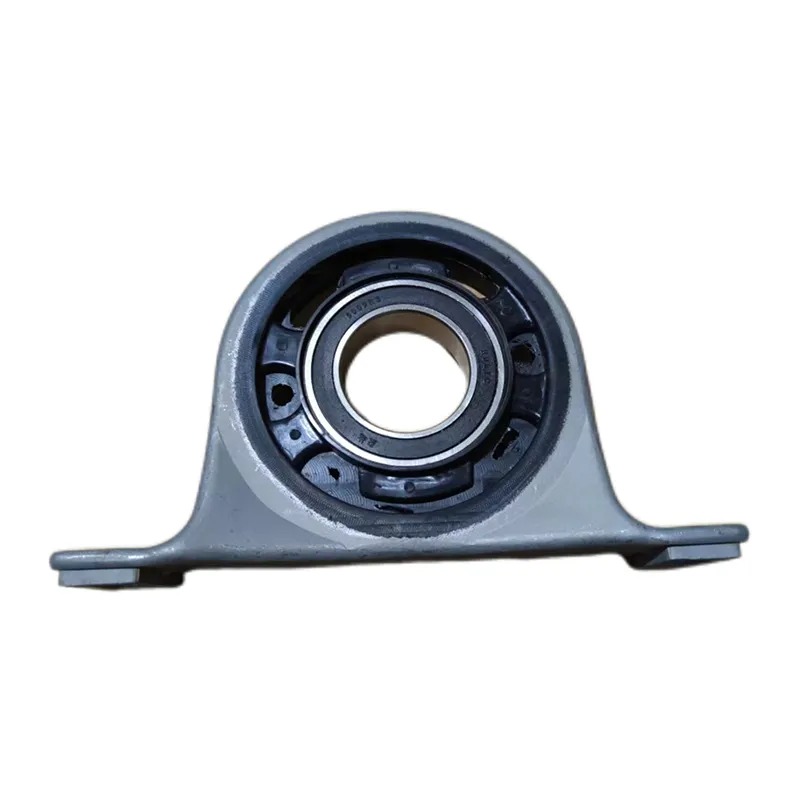

automobile control arm

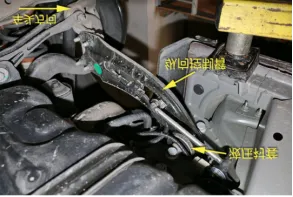

Automobile control arms, pivotal components in a vehicle's suspension system, maintain essential control over wheel alignment, ensuring stability and safety during driving. This article, crafted using expert knowledge and authentic experiences, delves into the nuances of control arms, highlighting their roles, functionality, and the critical considerations for maintenance and replacement.

Choosing replacement control arms demands keen attention to compatibility and quality. While aftermarket parts may present budget-friendly options, the reassurance of OEM (Original Equipment Manufacturer) parts cannot be overstated, as these parts assure perfect fitment and reliability. Trust in reputable brands and suppliers, corroborated by positive reviews and proven performance, fortifies one's confidence in these indispensable components. Installation of new control arms should always be followed by a professional wheel alignment to uphold the vehicle's integrity and prevent premature tire wear. Such vigilance underscores the trustworthiness of maintenance practices, ensuring not only the longevity of the control arm itself but also safeguarding the entire vehicular ecosystem. Ultimately, the lifetime of an automobile hinges significantly on the steadfastness of components like control arms. Applying expertise in their monitoring and maintenance yields profound benefits enhanced driving comfort, elevated safety, and prolonged vehicle health. Owners and professionals alike must commit to this meticulous stewardship, redefining vehicular longevity and performance in modern automotive dynamics. By fully understanding automobile control arms' importance and integrating this knowledge into routine maintenance practices, we ensure our vehicles operate safely and effectively, providing peace of mind for every journey.

Choosing replacement control arms demands keen attention to compatibility and quality. While aftermarket parts may present budget-friendly options, the reassurance of OEM (Original Equipment Manufacturer) parts cannot be overstated, as these parts assure perfect fitment and reliability. Trust in reputable brands and suppliers, corroborated by positive reviews and proven performance, fortifies one's confidence in these indispensable components. Installation of new control arms should always be followed by a professional wheel alignment to uphold the vehicle's integrity and prevent premature tire wear. Such vigilance underscores the trustworthiness of maintenance practices, ensuring not only the longevity of the control arm itself but also safeguarding the entire vehicular ecosystem. Ultimately, the lifetime of an automobile hinges significantly on the steadfastness of components like control arms. Applying expertise in their monitoring and maintenance yields profound benefits enhanced driving comfort, elevated safety, and prolonged vehicle health. Owners and professionals alike must commit to this meticulous stewardship, redefining vehicular longevity and performance in modern automotive dynamics. By fully understanding automobile control arms' importance and integrating this knowledge into routine maintenance practices, we ensure our vehicles operate safely and effectively, providing peace of mind for every journey.

Next:

Latest news

Upgrade Your Vehicle with Quality Control Arms

NewsNov.01,2024

Unlock Superior Performance with Our Control Arms for Sale

NewsNov.01,2024

Unlock Optimal Vehicle Performance with Diverse Control Arm Types

NewsNov.01,2024

Transform Your Ride with Lower Control Arm Replacement

NewsNov.01,2024

Revolutionize Your Ride with Control Arm Mounts

NewsNov.01,2024

Elevate Your Vehicle with Premium Control Arms

NewsNov.01,2024