High-Quality Control Arm Wholesale Supplier

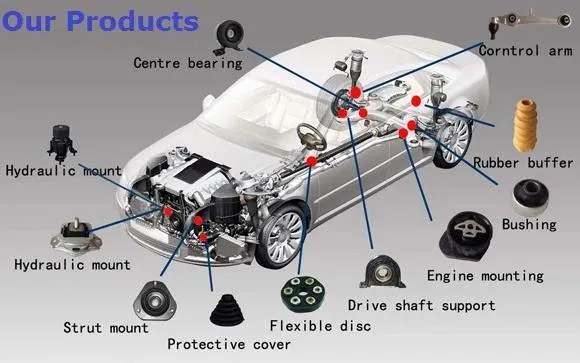

Control arms are a crucial component in the automotive suspension system, playing a vital role in ensuring vehicle stability, steering control, and overall safety. When considering a large-scale purchase in the realm of control arm wholesale, it is imperative to understand the nuances that contribute to a successful procurement strategy. This includes delving into the quality of products, the credibility of suppliers, and market dynamics affecting wholesale transactions.

Control arms are engineered to connect the vehicle’s suspension to the chassis, absorbing the shocks from the road, enabling a smoother ride. As such, quality is paramount when sourcing control arms for wholesale. Products made from high-quality materials, such as forged aluminum or stainless steel, offer superior durability and performance. Buyers can assess product quality by reviewing manufacturer certifications and testing results that ensure compliance with industry standards.

Expertise in evaluating control arms includes examining the different types used in various vehicle models. Control arms come in different configurations, such as upper and lower arms, and A-arms, depending on the vehicle design. Understanding the specific requirements of vehicles in your target market will optimize your inventory strategy.

The step to determining supplier expertise involves assessing their production capabilities and previous client testimonials. Reputable suppliers often have a long history in the automotive parts industry, consistently receiving positive feedback for their reliability and product consistency. Establishing a relationship with an authoritative supplier can enhance your brand’s reputation and ensure a steady supply of high-quality control arms. Suppliers frequently involved in cutting-edge automotive research often lead the market with innovative designs that enhance vehicle performance, providing a competitive edge in the wholesale market.

control arm wholesale

To build trustworthiness with potential partners and clients, transparency in business transactions is crucial. This can be achieved by implementing stringent quality control measures, providing clear documentation on the sourcing and manufacturing processes, and offering robust customer support. Transparent communication regarding the pros and cons of different products further cements trust with buyers.

Another vital aspect of the control arm wholesale business is understanding the market dynamics. Keeping abreast of industry trends, such as shifts towards eco-friendly manufacturing processes or the development of advanced composite materials, can help wholesalers adapt their inventory and sales strategies accordingly. Furthermore, participating in automotive trade shows and subscribing to industry publications bolsters market intelligence, offering insights into competitor strategies and potential collaboration opportunities.

Pricing strategy is also significant in wholesale operations. Competitively pricing your control arms while maintaining profitability requires a sound understanding of the cost components involved—from raw materials to manufacturing and logistics. Collaborating with data analysts to forecast demand fluctuations and optimize pricing models based on market trends ensures that your pricing remains attractive to buyers while safeguarding your business margins.

In conclusion, proficiency in the control arm wholesale domain demands a balanced application of experience, expertise, authority, and trustworthiness. Thoroughly evaluating the quality of control arms, carefully selecting credible suppliers, staying informed about market trends, and maintaining transparent business practices create a robust foundation for success. Businesses that excel in these areas can achieve a significant competitive advantage, providing customers with superior value in the dynamic automotive parts market.