2 月 . 18, 2025 06:50

Back to list

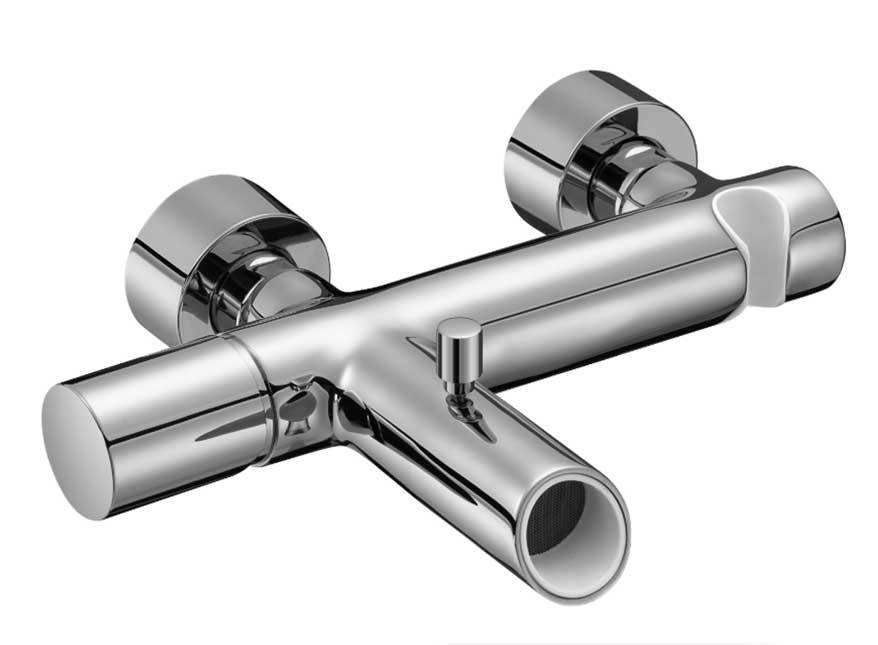

controller arm

The evolution of technology continues to shape industries, pushing the boundaries of what's possible. At the heart of many innovations is the controller arm, a crucial component that ensures precision and efficiency in various mechanical systems. From robotics to automotive manufacturing, the controller arm plays an indispensable role in streamlining operations and enhancing performance.

Authoritativeness in the field of controller arms comes from institutions and companies that lead in research and development. Institutions like MIT and companies such as FANUC are at the forefront, pioneering new technologies and setting industry standards. Their research projects and industrial applications often serve as benchmarks, influencing the design and functionality of controller arms globally. Trustworthiness is paramount when considering the implementation of a controller arm in any project. The stakes are high, particularly in sectors where precision and reliability are non-negotiable. Manufacturers and end-users alike must verify that the controller arms they employ adhere to strict industry certifications and standards. Regular maintenance and testing also play key roles in ensuring these components operate without fail, safeguarding both machines and the people who operate them. The future of controller arms is exciting, with developments in artificial intelligence and machine learning promising even more enhancements. The integration of these technologies is expected to further enhance the capabilities of controller arms, making them more autonomous and efficient. Speculative yet promising advancements such as adaptive learning algorithms may soon enable controller arms to learn from their tasks, optimizing their actions based on past performances and environmental conditions. In summation, the controller arm is far more than a mere mechanical component. It is a testament to human ingenuity and a critical element in modern industrial processes. As we advance, its role is expected to grow, making it a focal point for innovation and research. For industries relying on precision and efficiency, the continued development of the controller arm represents a pathway to unprecedented achievements and operational excellence.

Authoritativeness in the field of controller arms comes from institutions and companies that lead in research and development. Institutions like MIT and companies such as FANUC are at the forefront, pioneering new technologies and setting industry standards. Their research projects and industrial applications often serve as benchmarks, influencing the design and functionality of controller arms globally. Trustworthiness is paramount when considering the implementation of a controller arm in any project. The stakes are high, particularly in sectors where precision and reliability are non-negotiable. Manufacturers and end-users alike must verify that the controller arms they employ adhere to strict industry certifications and standards. Regular maintenance and testing also play key roles in ensuring these components operate without fail, safeguarding both machines and the people who operate them. The future of controller arms is exciting, with developments in artificial intelligence and machine learning promising even more enhancements. The integration of these technologies is expected to further enhance the capabilities of controller arms, making them more autonomous and efficient. Speculative yet promising advancements such as adaptive learning algorithms may soon enable controller arms to learn from their tasks, optimizing their actions based on past performances and environmental conditions. In summation, the controller arm is far more than a mere mechanical component. It is a testament to human ingenuity and a critical element in modern industrial processes. As we advance, its role is expected to grow, making it a focal point for innovation and research. For industries relying on precision and efficiency, the continued development of the controller arm represents a pathway to unprecedented achievements and operational excellence.

Next:

Latest news

Upgrade Your Vehicle with Quality Control Arms

NewsNov.01,2024

Unlock Superior Performance with Our Control Arms for Sale

NewsNov.01,2024

Unlock Optimal Vehicle Performance with Diverse Control Arm Types

NewsNov.01,2024

Transform Your Ride with Lower Control Arm Replacement

NewsNov.01,2024

Revolutionize Your Ride with Control Arm Mounts

NewsNov.01,2024

Elevate Your Vehicle with Premium Control Arms

NewsNov.01,2024