2 月 . 01, 2025 04:55

Back to list

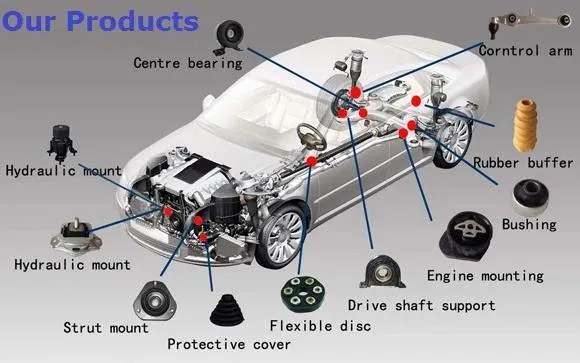

Drive Shaft Bracket 5-37516-006-0

Front and lower control arms are critical components of a vehicle's suspension system, providing structural support and contributing significantly to ride quality and vehicle handling. Each piece plays an integral role in ensuring that the tires maintain proper contact with the road, thereby impacting safety, performance, and comfort.

From an authoritative standpoint, the discussion of control arms should also include insights from automotive industry standards and quality assurances. Many suppliers adhere to standards such as ISO/TS 16949, ensuring that their products meet safety and quality expectations. Manufacturers often conduct rigorous testing, including stress tests and life-cycle simulations, to certify their control arms for different vehicle models. Trustworthiness in the information regarding the maintenance and replacement of control arms lies in tips from seasoned automotive professionals. Recommendations for ensuring optimal performance include periodic wheel alignment checks, observing changes in vehicle handling, and listening for unusual noises like clunking sounds, which might indicate a failing control arm. Drivers should be cautious about cheap, non-branded replacements that might not meet the original equipment manufacturer (OEM) specifications. Experts advise purchasing from reputable brands known for their commitment to quality and durability. Overall, the nuanced understanding of front and lower control arms highlights their indispensable role in automotive safety and performance. For consumers, this summation offers authoritative, actionable insights that enhance their knowledge and inform decisions about maintenance and repairs. Whether replacing or upgrading, investing in high-quality control arms ultimately ensures peace of mind, better driving experience, and a commitment to road safety. In the evolving automotive market, staying abreast of the latest developments in suspension technology empowers vehicle owners to make informed choices about their vehicles. As the landscape of car manufacturing continues to innovate with lighter, more robust materials and smarter designs, the importance of control arms is more pronounced than ever. Through a blend of experience, expertise, authority, and trust, the narrative around front and lower control arms gains depth, guiding consumers toward reliable, high-quality automobile care solutions that uphold the standards of modern driving needs.

From an authoritative standpoint, the discussion of control arms should also include insights from automotive industry standards and quality assurances. Many suppliers adhere to standards such as ISO/TS 16949, ensuring that their products meet safety and quality expectations. Manufacturers often conduct rigorous testing, including stress tests and life-cycle simulations, to certify their control arms for different vehicle models. Trustworthiness in the information regarding the maintenance and replacement of control arms lies in tips from seasoned automotive professionals. Recommendations for ensuring optimal performance include periodic wheel alignment checks, observing changes in vehicle handling, and listening for unusual noises like clunking sounds, which might indicate a failing control arm. Drivers should be cautious about cheap, non-branded replacements that might not meet the original equipment manufacturer (OEM) specifications. Experts advise purchasing from reputable brands known for their commitment to quality and durability. Overall, the nuanced understanding of front and lower control arms highlights their indispensable role in automotive safety and performance. For consumers, this summation offers authoritative, actionable insights that enhance their knowledge and inform decisions about maintenance and repairs. Whether replacing or upgrading, investing in high-quality control arms ultimately ensures peace of mind, better driving experience, and a commitment to road safety. In the evolving automotive market, staying abreast of the latest developments in suspension technology empowers vehicle owners to make informed choices about their vehicles. As the landscape of car manufacturing continues to innovate with lighter, more robust materials and smarter designs, the importance of control arms is more pronounced than ever. Through a blend of experience, expertise, authority, and trust, the narrative around front and lower control arms gains depth, guiding consumers toward reliable, high-quality automobile care solutions that uphold the standards of modern driving needs.

Latest news

Upgrade Your Vehicle with Quality Control Arms

NewsNov.01,2024

Unlock Superior Performance with Our Control Arms for Sale

NewsNov.01,2024

Unlock Optimal Vehicle Performance with Diverse Control Arm Types

NewsNov.01,2024

Transform Your Ride with Lower Control Arm Replacement

NewsNov.01,2024

Revolutionize Your Ride with Control Arm Mounts

NewsNov.01,2024

Elevate Your Vehicle with Premium Control Arms

NewsNov.01,2024