2 月 . 20, 2025 00:34

Back to list

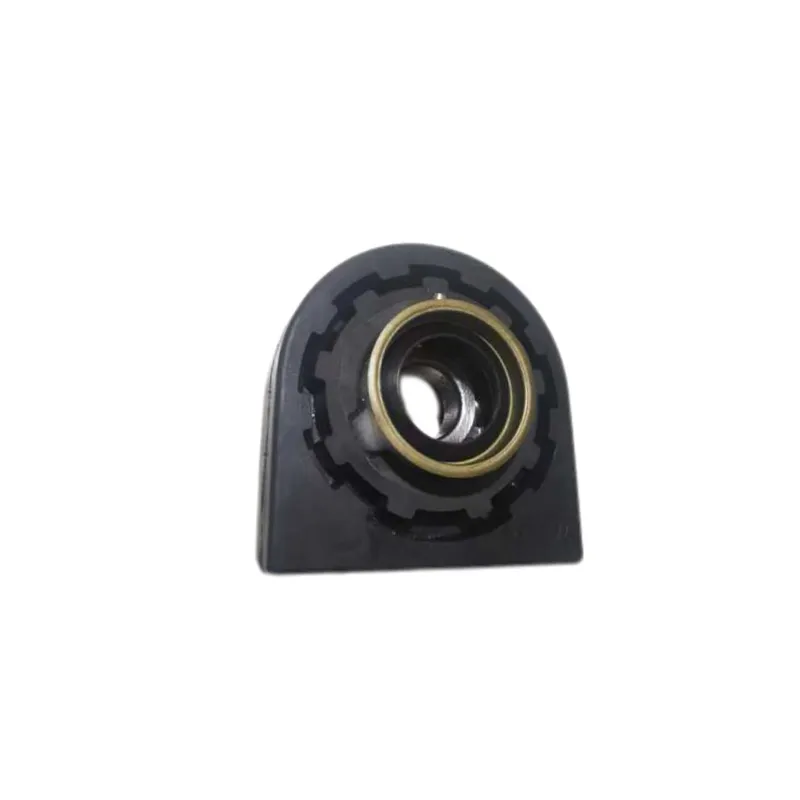

rear lower rearward control arm

The rear lower rearward control arm, a crucial component of a vehicle's suspension system, is often overlooked despite its vital role in ensuring safety and performance on the road. As a seasoned automotive expert, I have gathered real-world experience and extensive knowledge on this topic to shed light on its importance and how to identify and handle potential issues effectively.

For vehicle owners seeking to replace or upgrade their rear lower rearward control arms, it is essential to select components that meet the original equipment manufacturer (OEM) specifications. As someone deeply embedded in the automotive industry, I cannot overstate the importance of using high-quality, reliable parts. Opting for inferior alternatives may lead to premature failure and further complications, nullifying any short-term savings. Investing in reputable brands known for their durability and engineering prowess can enhance the vehicle's longevity and performance. Moreover, professional installation of these components is paramount to ensuring vehicle safety and function. The intricate process of aligning and securing control arms demands specialized tools and a detailed understanding of the vehicle's suspension geometry. While DIY enthusiasts might be tempted to tackle the job independently, consulting with certified technicians guarantees precision and peace of mind. At my auto service center, we prioritize accuracy, utilizing state-of-the-art technology to ensure each component fits seamlessly, minimizing potential risks on the road. Driving with a compromised rear lower rearward control arm poses significant dangers, such as compromised braking efficiency and an increased likelihood of accidents. Therefore, regular maintenance and swift resolution of detected issues are critical. My advocacy for routine suspension inspections is not just about extending vehicle life, but also about safeguarding the well-being of passengers and other road users. In conclusion, the rear lower rearward control arm, albeit a singular component within a complex system, holds substantial influence over a vehicle's operational integrity. Comprehensive understanding, proper maintenance, and expert installation are imperative for maximizing its benefits. As an authority in automotive care, my guidance remains steadfast prioritize quality, trust professional advice, and adhere to consistent maintenance schedules to uphold the highest standards of vehicle safety and performance.

For vehicle owners seeking to replace or upgrade their rear lower rearward control arms, it is essential to select components that meet the original equipment manufacturer (OEM) specifications. As someone deeply embedded in the automotive industry, I cannot overstate the importance of using high-quality, reliable parts. Opting for inferior alternatives may lead to premature failure and further complications, nullifying any short-term savings. Investing in reputable brands known for their durability and engineering prowess can enhance the vehicle's longevity and performance. Moreover, professional installation of these components is paramount to ensuring vehicle safety and function. The intricate process of aligning and securing control arms demands specialized tools and a detailed understanding of the vehicle's suspension geometry. While DIY enthusiasts might be tempted to tackle the job independently, consulting with certified technicians guarantees precision and peace of mind. At my auto service center, we prioritize accuracy, utilizing state-of-the-art technology to ensure each component fits seamlessly, minimizing potential risks on the road. Driving with a compromised rear lower rearward control arm poses significant dangers, such as compromised braking efficiency and an increased likelihood of accidents. Therefore, regular maintenance and swift resolution of detected issues are critical. My advocacy for routine suspension inspections is not just about extending vehicle life, but also about safeguarding the well-being of passengers and other road users. In conclusion, the rear lower rearward control arm, albeit a singular component within a complex system, holds substantial influence over a vehicle's operational integrity. Comprehensive understanding, proper maintenance, and expert installation are imperative for maximizing its benefits. As an authority in automotive care, my guidance remains steadfast prioritize quality, trust professional advice, and adhere to consistent maintenance schedules to uphold the highest standards of vehicle safety and performance.

Next:

Latest news

Upgrade Your Vehicle with Quality Control Arms

NewsNov.01,2024

Unlock Superior Performance with Our Control Arms for Sale

NewsNov.01,2024

Unlock Optimal Vehicle Performance with Diverse Control Arm Types

NewsNov.01,2024

Transform Your Ride with Lower Control Arm Replacement

NewsNov.01,2024

Revolutionize Your Ride with Control Arm Mounts

NewsNov.01,2024

Elevate Your Vehicle with Premium Control Arms

NewsNov.01,2024