2 月 . 04, 2025 03:15

Back to list

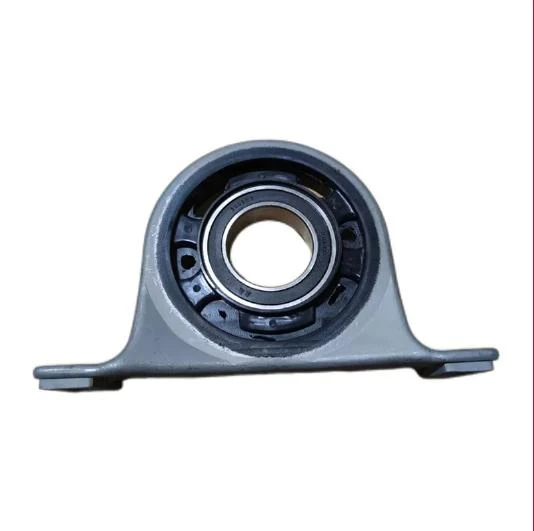

upper and lower control arms with ball joints

The importance of upper and lower control arms with ball joints in a vehicle's suspension system cannot be overstated. These components play a critical role in ensuring smooth handling and safe driving. By understanding their function, benefits, and maintenance, drivers can make informed decisions, optimize vehicle performance, and enhance safety.

Choosing high-quality upper and lower control arms with ball joints is imperative for maintaining vehicle integrity. Investing in components from reputable manufacturers guarantees durability and performance. Many high-quality control arms are made from materials like forged steel or aluminum, which offer strength and resistance to corrosion. Such materials not only extend the lifespan of the components but also maintain the safety and handling characteristics of the vehicle. For those looking to upgrade their vehicle's suspension, aftermarket options are available that offer enhanced performance features. These upgrades can include adjustable control arms, which allow for better alignment customization, or performance ball joints designed for improved steering response in high-performance driving conditions. Enthusiasts often opt for these upgrades to achieve a more precise driving experience and improved vehicle dynamics. To foster a culture of trust and reliability among consumers, manufacturers should adhere to rigorous testing standards and provide comprehensive warranties. This transparency not only builds consumer confidence but also reinforces the importance of maintaining high standards in automotive manufacturing. In conclusion, upper and lower control arms with ball joints are vital components of a vehicle's suspension system, providing crucial support for steering and stability. Regular inspection, maintenance, and opting for high-quality replacements ensure both safety and performance are upheld. For those seeking enhanced driving dynamics, performance upgrades offer viable solutions while maintaining the fundamental functions of the suspension system. Prioritizing the quality and integrity of these components underscores a commitment to vehicle safety and optimal performance.

Choosing high-quality upper and lower control arms with ball joints is imperative for maintaining vehicle integrity. Investing in components from reputable manufacturers guarantees durability and performance. Many high-quality control arms are made from materials like forged steel or aluminum, which offer strength and resistance to corrosion. Such materials not only extend the lifespan of the components but also maintain the safety and handling characteristics of the vehicle. For those looking to upgrade their vehicle's suspension, aftermarket options are available that offer enhanced performance features. These upgrades can include adjustable control arms, which allow for better alignment customization, or performance ball joints designed for improved steering response in high-performance driving conditions. Enthusiasts often opt for these upgrades to achieve a more precise driving experience and improved vehicle dynamics. To foster a culture of trust and reliability among consumers, manufacturers should adhere to rigorous testing standards and provide comprehensive warranties. This transparency not only builds consumer confidence but also reinforces the importance of maintaining high standards in automotive manufacturing. In conclusion, upper and lower control arms with ball joints are vital components of a vehicle's suspension system, providing crucial support for steering and stability. Regular inspection, maintenance, and opting for high-quality replacements ensure both safety and performance are upheld. For those seeking enhanced driving dynamics, performance upgrades offer viable solutions while maintaining the fundamental functions of the suspension system. Prioritizing the quality and integrity of these components underscores a commitment to vehicle safety and optimal performance.

Latest news

Upgrade Your Vehicle with Quality Control Arms

NewsNov.01,2024

Unlock Superior Performance with Our Control Arms for Sale

NewsNov.01,2024

Unlock Optimal Vehicle Performance with Diverse Control Arm Types

NewsNov.01,2024

Transform Your Ride with Lower Control Arm Replacement

NewsNov.01,2024

Revolutionize Your Ride with Control Arm Mounts

NewsNov.01,2024

Elevate Your Vehicle with Premium Control Arms

NewsNov.01,2024